Machinery

Recycling

Recycling

Rag Tearing Machines

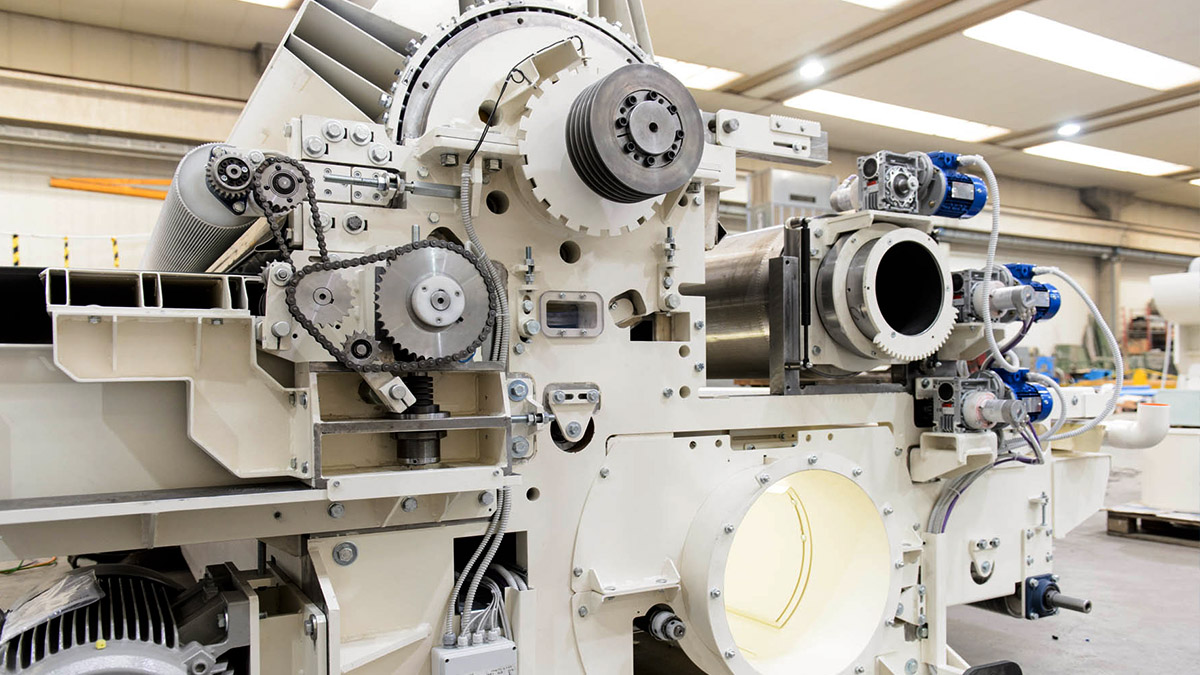

The new version of the G101, the SF 2000 offers some significant innovations which improve the performance of the machine and increase its efficiency and reliability.

Also this machine works on the principle by which, especially with wide working width, the application of a feeder on each tearing drum allows a more uniform feed of the material, and improves the working conditions of the drum. This gives better quality results, that are definitely superior to those of machines with drums in a line.

The condensers, which in previous models sucked up the material at the outlet of one cylinder to load it into the following cylinder’s feeder of the following one, have been eliminated from the SF 2000, and now the fibers pass from one to the next drum thanks to ventilation and centrifugal force generated by the previous drum, and also thanks to an air flow system. This gives good results in terms of technologic air abatement, blocking point elimination and machine maintenance reduction.

To prevent the first roller from receiving too much waste material from the other rollers, the dropped material is recovered and recycled onto the roller from which it has dropped, rather than being returned to the start of the line.

The drive system of the SF 2000 is also new, with its series of AC motors controlled by a single frequency inverter which works when the individual rollers are started or stopped. This optimises energy consumption and allows for a reduction in the overall power installed.

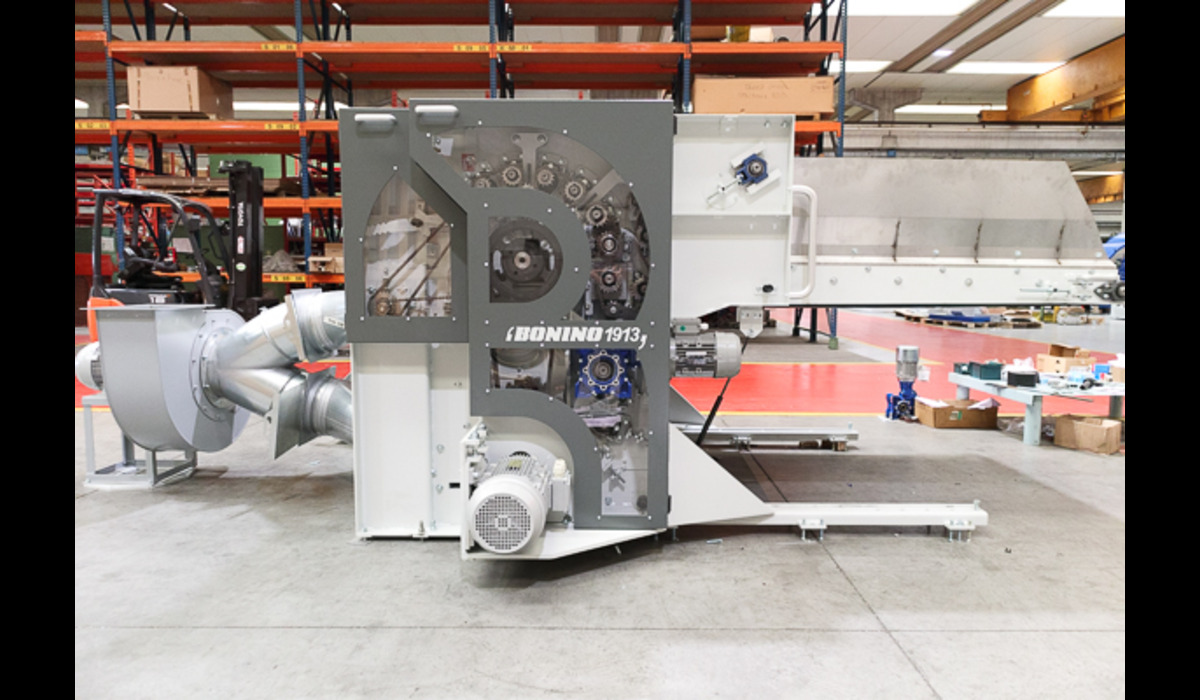

Bonino Carding Machines offers rotary cutters in 3 different working widths: 1250, 1500 and 1800.

The special shape of the rotating blades, integrated in a spiral on the cylinder, guarantees high production up to a working width of 1800. The cutting is achieved by means of rotating blades that work in conjunction with the fixed blade (with length equal to the working height of the machine).

Each cylinder carries 3 groups of blades whose dimensions vary depending on the working width (from 205 to 300 mm). The compact blade allows high production speeds, limited maintenance, and less strain on the machine.

• Adjustable cutting length

• Option to install an automatic feeder to load the material onto the feeding belt

• Option of output magnet for the collection of metal contaminants