Company

Company

The entire production cycle, from design to production, takes place within our own 13,000 square meter own factory.

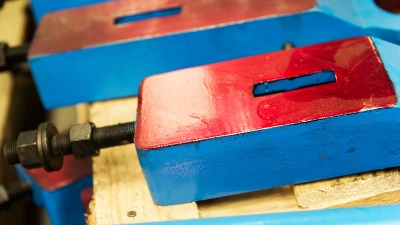

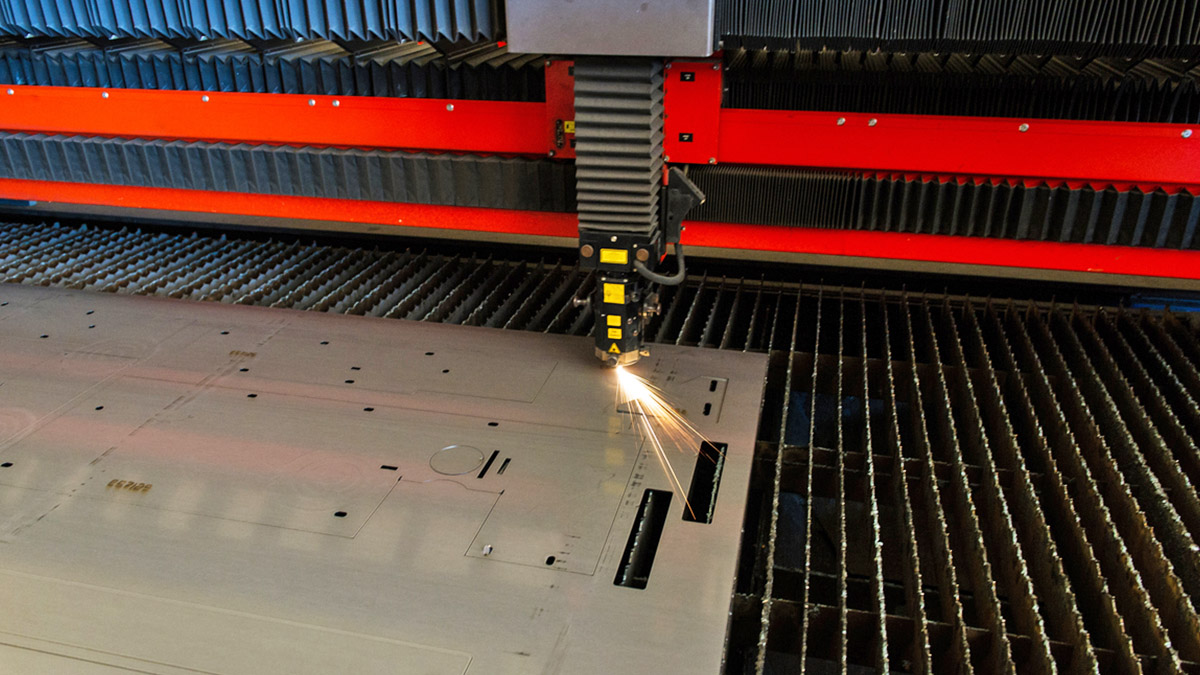

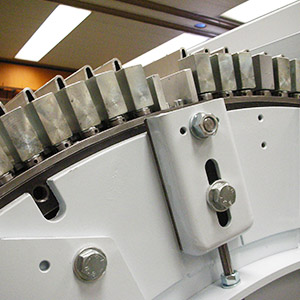

Research, development, production, and application of new technologies, is managed directly by our technical office, within the framework of our production department. High-performance machinery, combine with skilled, highly experienced personnel to ensure that projects take shape with constant dialogue with the customer, during each step of the project.

Our philosophy is to design and build the entire machine, utilising our own production facilities to manufacture the parts in conjunction with specialised components from trusted partners. In addition, assembly, testing and verification is carried out in-house.

This approach allows us to strictly manage quality and delivery time, whilst ensuring a wide range of spare parts is constantly available.

History

-

1900

Bonino Carding Machines was born in Biella at the beginning of the 20th century while the area was becoming internationally famous at an international level for the production of high-quality yarns and textile fabrics. Bonino, which initially produced components and then carding sets, worsted and semi-worsted cards, consolidates its position among the leaders of the carding sector in the postwar period, when cars start to spread and all the sectors linked to them undergo a real boom. It designs nonwoven cards to apply to the automotive sector, which are suitable to produce items for padding, mattress or materials destined to other industrial sectors such as filtration, packaging and sanitary.

-

1980

In the 80s it develops the flat card for regenerated fibres that, presented at the Itma of Milan in the year 1983, marks the entrance of Bonino Carding Machines among the producers of cotton machines. In this period too, it purchases a company manufacturing cutters and rag tearing machines, it studies and improves machines to blend fibres (blending chambers and mixers), to open (bale-breakers and openers), clean and store.

-

2016

Nowadays, Bonino Carding Machines is the only company in the world able to set up a complete system from the cut of waste to the carding process in the sectors using "recycled" materials.