Machinery

Wollen

Wollen

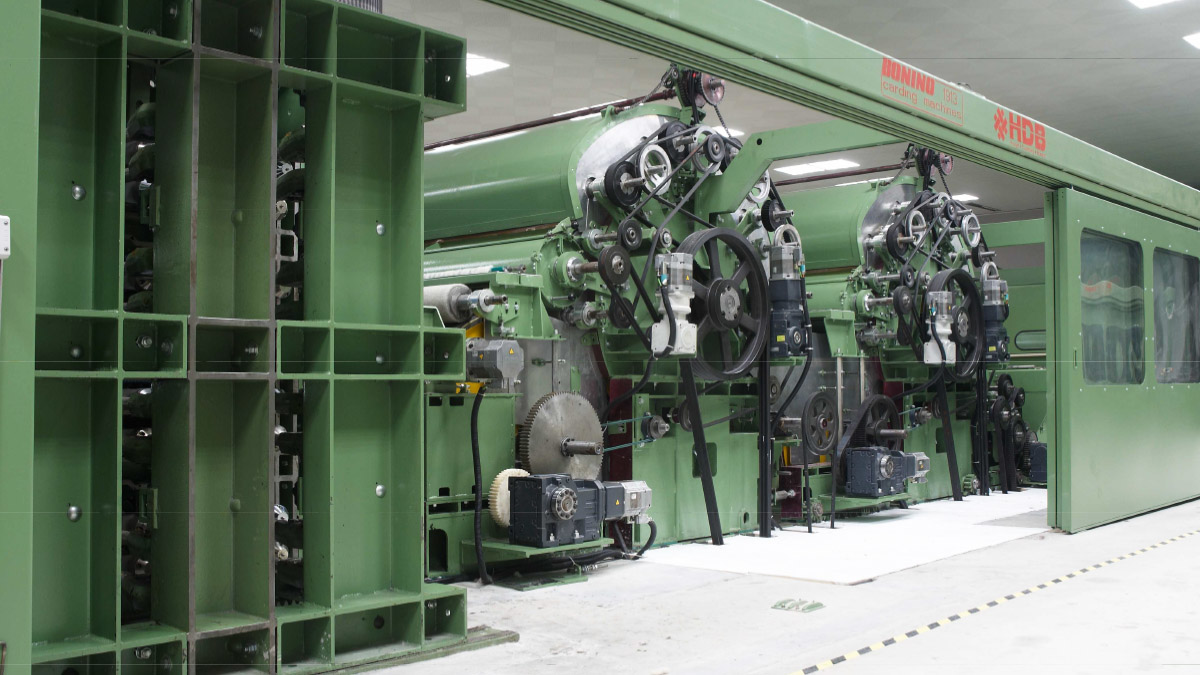

Bonino Carding Machines was established in Biella at the beginning of the 20th Century. Throughout its proud history the company has continuously invested in research and development in order to produce the most innovative machinery. As a result, Bonino is internationally well known as a leader in the field of woollen carding and associated machinery. This has been confirmed by the acquisition of the Belgian Company HDB, which also boast a long history in the same field.

Bonino's expertise in the Woollen Processing Industry includes a full range of the most efficient and modern fibre preparation machines.

Individual machines can be integrated into existing lines, or complete lines can be provided.

A full range of options is available, from manually fed systems, semi-automatic systems or completely automatic blending lines.

In order to ensure a precise feed, and consequent regularity of loading, Gravimetric or Volumetric hopper feeders complete with the latest control systems, are installed at the entry to the card.

A Peralta device crushes natural impurities vegetation at pressures of up to 3000 kg.

The machines can be equipped with intermediate feeds in a variety of options, from broad-band or parallel fibre feeds with conveying either overhead or underground.

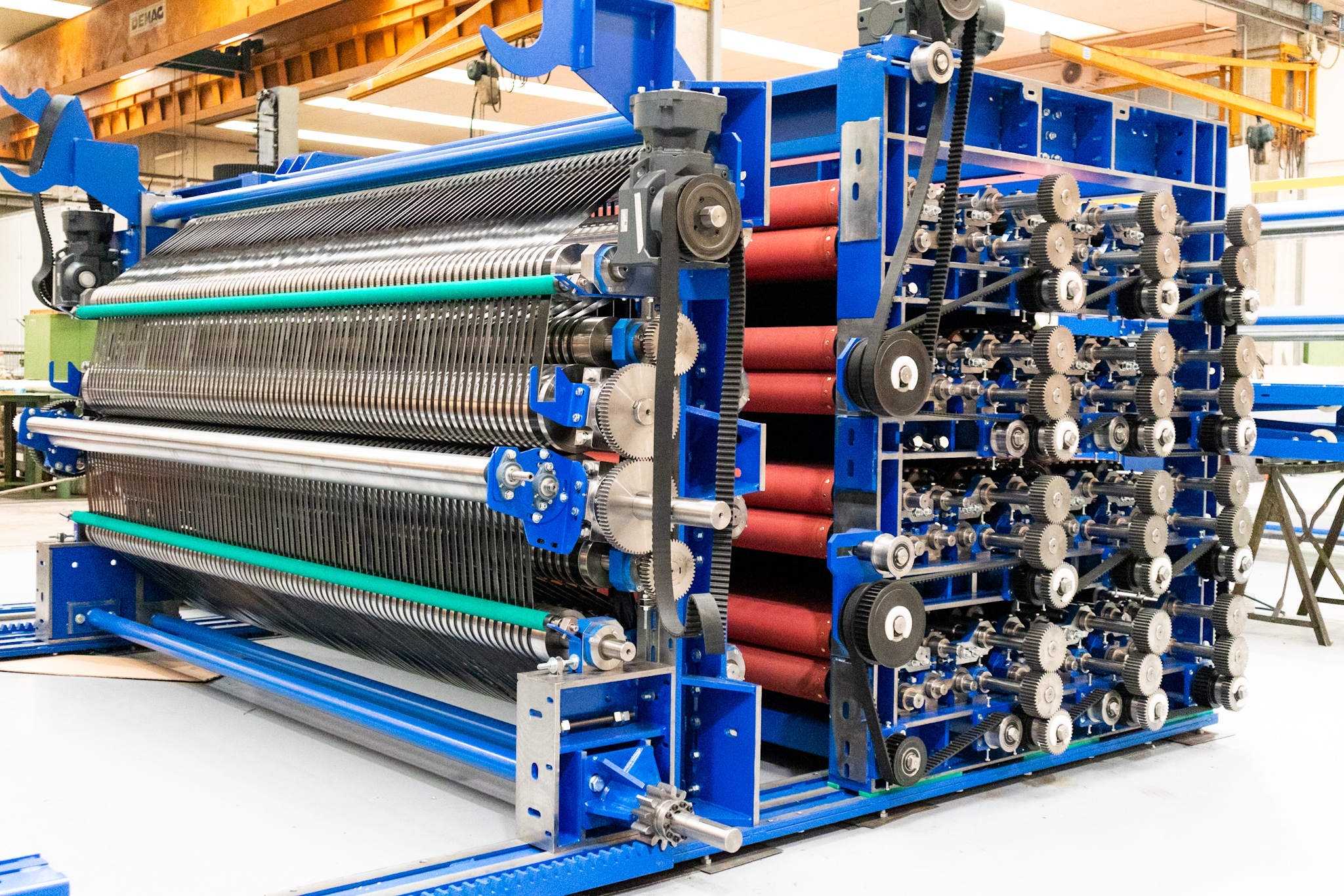

Optimum distribution of working elements throughout the machine ensures progressive carding in order to achieve high quality slubbing in both fine and course counts. Bonino HDB has the skill and experience to determine the best configuration depending on the fibre type and the count of yarns to be produced.Yarn counts between 0,2 NMto 30 NM can be produced.

Woollen Carding sets are available in widths from 1500 up to 3000 mm. For the production of regenerated fibres a cylinder diameter of 2000 mm is available.For high working precision, all Bonino HDB cylinders are engineered and balanced statically and dynamically. The mechanical balancing is made at the working speed of the cylinder while a very precise rectifying system assures 0,01 mm of tolerance on the circumference and 0,03 mm on the working width.

Web dividing systems are available with "endless" tape, "series" (2 tapes - 2 ends) or "figure 8" (one tape - two ends).

Rubbing systems can be single, double or triple.

As a result of the merging of technologies from Bonino and HDB, tandem and super-traversing creels are available.

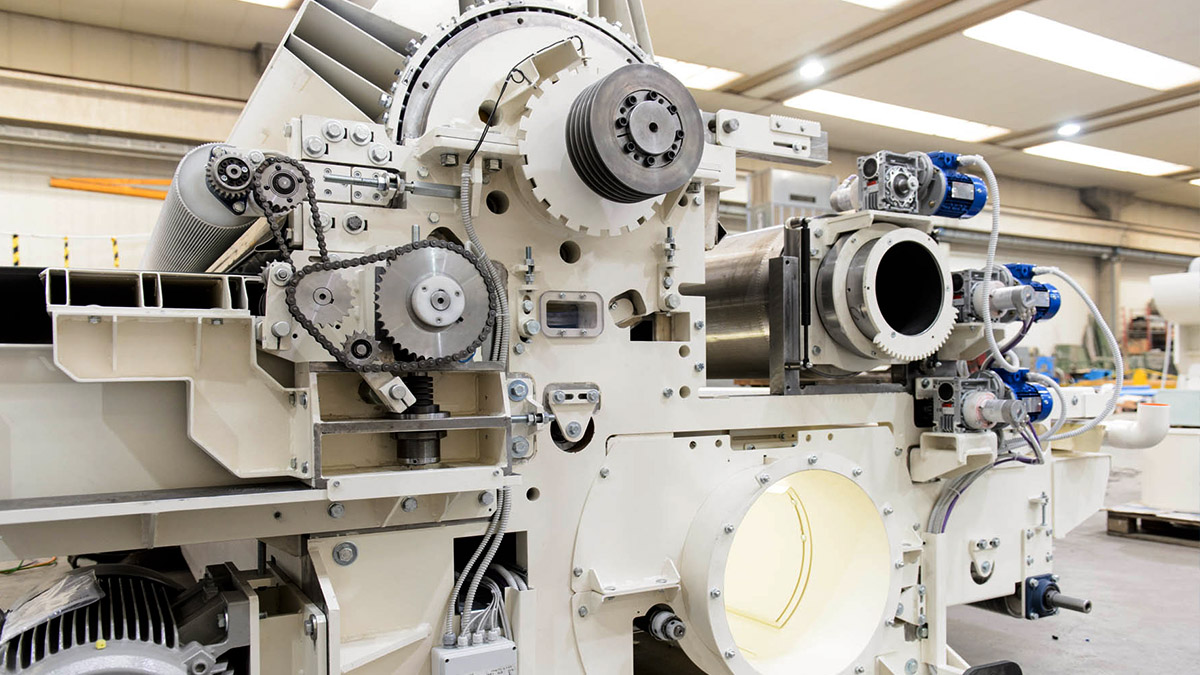

Electrical drive systems are available with standard AC motors with inverter where required.

Alternatively Bonino has developed a servo motor solution, which utilises common motor sizes to all driven elements. The result is a machine with 23 identical 3.3 kw motors meaning that only one 800 spare is required for an entire machine.

Cylinders and tape condenser column motors are supplied with AC frequency inverters as standard. The machine can be supplied with "Tele-Service" which allows remote diagnostics directly from the Bonino technical office. In addition, an optional video camera system is available to monitor critical parts of the machine, such as the draft.